powering the next wave of advancement for AI

AI for factories is being powered for the next wave in Taiwan.Fibre optic connections have become a crucial component in enabling the scale and speed that AI companies need as the technology continues to transform the global economy.

At its centre are optical transceivers, a little-known but crucial component. To lead this field, FIC Global Inc. (TWSE: 3701; FICG), a top specialist in semiconductor packaging and installation on optical modules, is using its more than 16 years of experience to develop them.

“The full potential of AI will only be unleashed when data can move at light speed among AI cluster networks,” remarked Mr. Leo Chien, Chairman of FICG. “That’s why we’ve spent over a decade building the process leadership and technologies to make the most advanced optical transceivers for AI factories.”

FIC Global is powering the next wave of advancement for AI with leading-edge optical transceivers up to 1.6T and beyond.

Enabling breakthrough capabilities for AI factories

Future AI factories must have high speed and low latency at scale, as well as increased energy efficiency to reduce high power requirements. However, the performance and data transfer of electrical connections are constrained. Connecting AI clusters with fibre optics provides the following benefits:

- Unmatched bandwidth and low latency

- Energy efficiency

- Infrastructure scalability

Optical transceivers, the essential part, greatly speed up data transfer between compute nodes by converting electrical signals into light data for transmission over fibre optic cables. Companies like FICG are developing to double speeds in the future, with 1.6 terabits (T) per second being the new benchmark for data transmission speeds this year [2025].

FICG: A decade of engineering in optical communications

Since 2008, FICG has supplied optical transceivers for cloud computing, enterprise networks, data centres, and telecoms, bringing with it over 16 years of experience in process leadership and manufacturing technology. The corporation has a significant edge to capitalise on the current AI boom because of its early leadership in optical communications.

From 2008 to 2020, when it included chips-on-board, FICG made significant technological advancements:

- 2008: Established the foundation for optical module manufacturing with 1.25G small form factor and 2G copper modules

- 2010: Enhanced capabilities by launching 2G and 4G small form-factor pluggable modules

- 2012: Further expanded by introducing 8G, 10G, and 40G modules

- 2014: Launched the first 100G modules and entered the high-speed module segment with 100G C-Wire, 100G C form-factor pluggable, and 100G Topaz modules

- 2016: Introduced 400G applications and achieved commercialisation of the latest 100G modules

- 2018: Further advanced 400G, 200G, and 100G solutions to support diverse high-speed switching and optical transport architectures

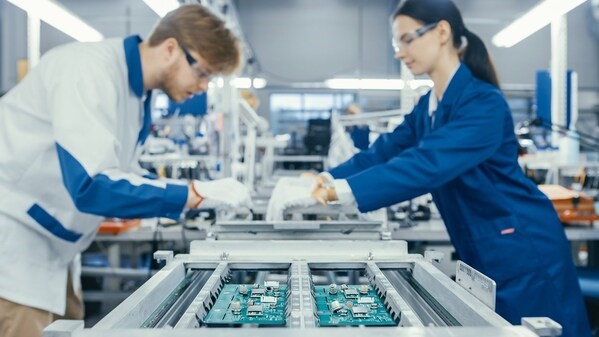

FICG’s competitive vertically integrated model and process leadership are responsible for these accomplishments. High-performance, high-precision printed circuit board assembly (PCBA) and joint design manufacturing (JDM) are its main areas of concentration. Semiconductors are then packaged with PCBs [printed circuit boards].

FICG allows clients to streamline their supply chains for optical modules by combining more advanced manufacturing techniques, such as 2.5D and 3D semiconductor packaging and bare-die flip chip installation, with the more widely used surface mount technology for the remainder of a PCB [printed circuit board].

The company also became proficient in ultra-miniaturisation manufacturing procedures early on, which included installing components with diameters as thin as a hair’s breadth, such as 008004 (0.25×0.125 mm), 01005 (0.4×0.2 mm), and 0201 (0.6×0.3 mm).

These days, FICG works closely with semiconductor makers and provides significant players around the world. It has a 20% global market share in 400G, an 18% market share in 800G, and is leading the newest 1.6T segment while developing toward 3.2T.

Source:FIC Global, Inc.