innovation in oil & gas equipment

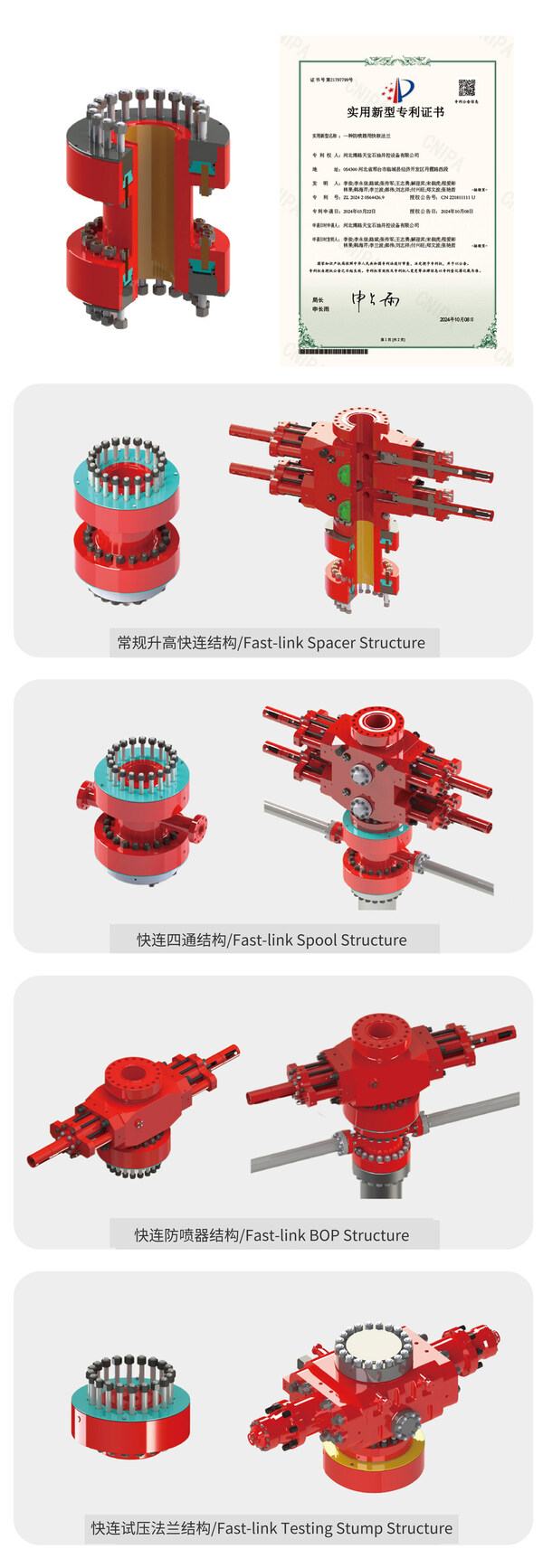

The INTLEF Group unveiled the Quick-Connect Flange, a ground-breaking innovation designed to solve industrial problems and improve connection techniques [March 2025].It makes it possible to connect API 6A standard flanges—such as pressure test, BOP, and wellhead flanges—efficiently. Flange connections in other mechanical systems can also use it.

Flanges, which are symmetrical disc-like parts, are used to seal or fasten pipes, containers, or mechanical parts with fixed shafts.

INTLEF Oil and Gas Group is a global business that specializes in EOR services, oilfield supplies international commerce, EPC projects, manufacturing, operation, and maintenance of petroleum equipment, and research and development.

Key Technical Innovations

There are two types: studded connections and flange connections. High-pressure hydraulic oil is used in its core technology to facilitate quick and safe couplings between flanges and pistons.

The noteworthy benefits include:

1. Considerable Time and Money Savings

reduces the time needed for wellhead and BOP flange procedures by 75–90% during installation and disassembly; reduces labor effort by 95%; works with hydraulic pressures between 10 and 20 MPa; works with BOP control systems already in place, so no additional hydraulic control setups are required; and increases operating efficiency while drastically cutting expenses.

2. Increased Security

Removes the need for sledgehammers, torque tools, or hammer wrenches to streamline processes and guarantee safety, particularly for work done at heights. Connection security is improved by automated hydraulic action, which guarantees consistent flange bolt tension.

3. Better Sealing Results

High connection dependability and tightness are ensured by hydraulic operation, which distributes stress evenly on sealing rings.

4. Less Wear on Equipment

Avoids premature component damage, by not applying excessive torque to bolts and nuts.

Structural Designs and Applications

1. Standard Elevated fast-Connect Structure: This structure helps to elevate short sections and has fast-connect structures on both ends for easy connections between two flanged devices.

2. Quick-Connect drilling spool Structure: This feature keeps the quick-connect structures on both ends while adding two side outputs to the body. It serves as the drilling spool and enables fast connections between two devices that share a flange, particularly in applications requiring small spaces.

3. BOP easy-Connect Structure o Allows for easy connections with other BOP or wellheads that share a flange by integrating the quick-connect structure straight into the BOP body flange.

4. Flange Structure for Pressure Tests Well control workshops, production facility test stations, BOP maintenance/overhaul, and other test applications use the quick-connection structure, which is designed as a unique flange and used as a test flange, test pile, or base, etc., requiring frequent disassembly and pressure tests.

The design, production, testing, and optimisation of the Quick-Connect Flange took more than a year to complete. Prior to debut, extensive real-world operational testing revealed the product’s exceptional performance, garnering positive feedback from customers.

The Quick-Connect Flange represents INTLEF’s dedication to influencing the direction of the industry and goes beyond simply a product. The company hopes to start a new era in the development of oil and gas equipment through constant innovation and cooperation with international partners.

Picture Source: INTLEF Oil and Gas Group